Modular inverter system

T6 APD

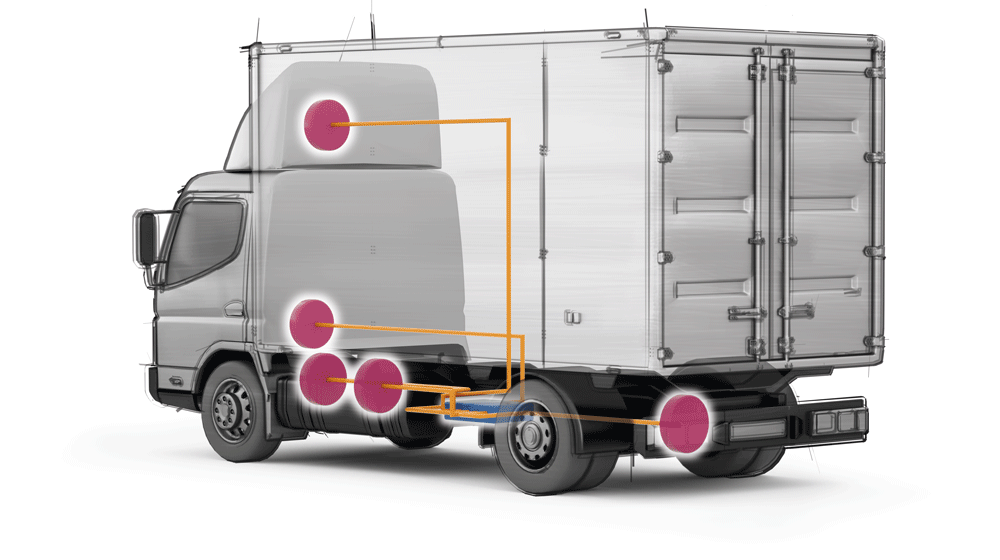

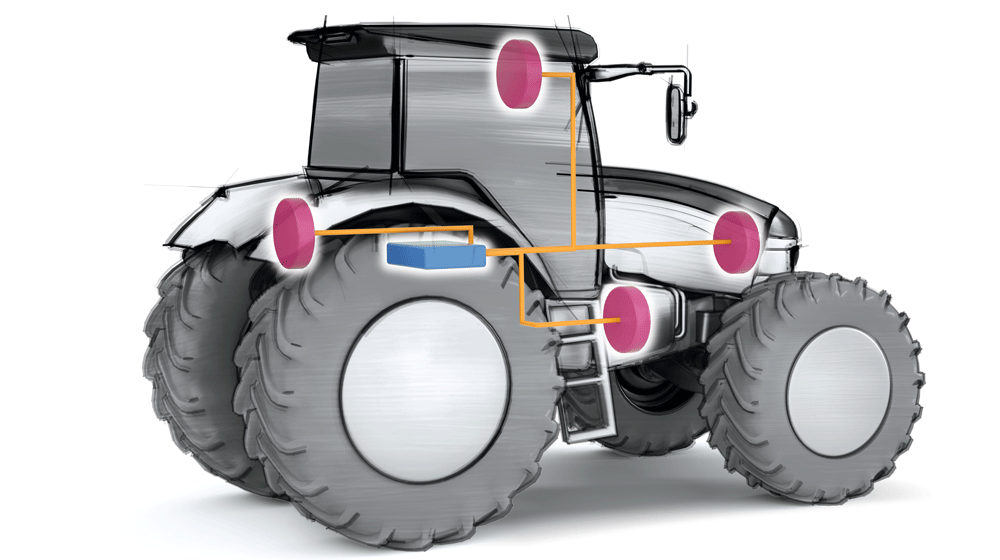

Electrify auxiliary systems in vehicles with the T6 APD inverter system from KEB Automation. The T6 APD is designed for electric vehicles running on batteries or hybrid applications, and meets all requirements placed on electronic components or systems in relation to mechanical and thermal properties, ambient conditions, EMC, safety or service life.

The scalable and modular T6 APD system can be flexibly adapted to different vehicle requirements, and enables the integration of up to six inverter modules available in three different performance levels with rated output currents of 16.5 A, 33 A and 60 A. The T6 APD reliably handles dynamic and energy-efficient speed and torque control tasks.

The integrated mobile control system (MCU) offers the possibility of developing new automation solutions for electric vehicles and mobile machines. A communication gateway for higher-level vehicle control is available in the form of J1939 CAN and UDS APP. DC EMC filters, integrated as standard, also ensure a high degree of operational reliability in combination with other high-voltage components in the vehicles.

Highlights

- All-in-one solution

- DCU – scalable DC-AC drive controller with a rated output current of up to 60 A

- E1 type approval and certification according to ECE R10, optional CE marking possible

- MCU – mobile control system

- J-1939 CAN, UDS, TSC – torque and speed control

- Application software (air compressor, steering pump, heat pump, etc.)

Tim Hagemeier

Sales Automotive - e-mobility

ALL-IN-ONE PRINCIPLE

The T6 APD makes the electrification of auxiliary drives in vehicles noticeably easier. Via a mobile control system that is already available, integrated EMC filters and the integration of up to six inverter modules, the T6 APD system provides users with the ideal requirements for quick and easy start-up with no extra effort. Advanced control algorithms for electric motors in vehicles guarantee maximum efficiency.

- Power electronics for controlling electric auxiliary drives in commercial vehicles

- PMSM, ASM: dynamic and energy-efficient speed and torque control

- Encoderless operation: automatic detection of motor resistance, inductance and rotor position

- Magnet-free motors, synchronous reluctance motors, axial flux motors

- High-speed applications up to 2,000 Hz

Mobile Automation Control

KEB Automation offers you various application-specific software solutions for the electrified operation of auxiliary systems in vehicles – such as for air compressors, servo or heat pumps, speed or torque control or generator applications.

- Intelligent PLC (CODESYS)

- IEC 61131-3 environment, freely programmable

- CANopen and J1939 communication gateway for exchanging process data, parameters and diagnostics messages

- UDS services

Technical data

| HV-DC input voltage range | 200 … 820 V DC | ||||

|---|---|---|---|---|---|

| Nominal DC input current | 120 A | ||||

| Maximum DC input current for 60 s | 180 A | ||||

| Rated output current at fS = 8 kHz | 16.5 A (DCU A) | 33 A (DCU B) | 60 A (DCU C) | ||

| LV-DC input voltage range | 9 … 32 VD C | ||||

| Motor temperature monitoring | PTC, KTY84, PT1000 |

| Surrounding temperature in operation | -30 … 70 °C (ISO 16750-4 Code Z) | ||||

|---|---|---|---|---|---|

| Degree of protection | IP67, IP6K9K | ||||

| Mechanical ambient conditions, shock and vibration | ISO 16750-3 Code L | ||||

| Liquid cooling – Water-glycol coolant flow rate | 10 l/min | ||||

| Coolant inlet temperature | constant, maximum 65° C |

| Electromagnetic compatibility tested according to ECE R10 - E1 type approval | |||||

|---|---|---|---|---|---|

| Integrated common-mode-DC-EMC filter | |||||

| Shifted switching of IGBT modules | |||||

| EMC connectors – optimal shield connection and cable clamping | |||||

| UN ECE R10: Rev.5, E1*10R05/01*8958*00, CISPR25 |

System configuration

| MCU | DCU_1 | |||

| EMC Filter | ||||

| Basic unit | Nominal current | DCU Modules | Lenght | Weight |

| System configuration | IN / A (fs = 8 kHz) | qty | mm | kg |

| C | 60 |

1 |

346 | 9.5 |

| B | 33 | 8.9 | ||

| A | 16.5 | 8.7 | ||

| MCU | DCU_1 | DCU_2 | |||

| EMC filter | EMC filter | ||||

| Basic unit | Nominal current | DCU Modules | Length | Weight | |

| System configuration | IN / A (fs = 8 kHz) | qty | mm | kg | |

| CC | 60 | 60 | 2 | 496 | 14.7 |

| CB | 60 | 33 | 14.1 | ||

| CA | 60 | 16.5 | 14 | ||

| BB | 33 | 33 | 13.5 | ||

| BA | 33 | 16.5 | 13.4 | ||

| AA | 16.5 | 16.5 | 13.3 | ||

| MCU | DCU_1 | DCU_2 | DCU_3 | |||

| EMC filter | EMC filter | EMC filter | ||||

| Basisgerät | Nominal current | DCU Modules | Lenght | Weight | ||

| System configuration | IN / A (fs = 8 kHz) | qty | mm | kg | ||

| CCC | 60 | 60 | 60 | 3 | 646 | 19.8 |

| CCB | 60 | 60 | 33 | 19.2 | ||

| CCA | 60 | 60 | 16.5 | 19.1 | ||

| CBB | 60 | 33 | 33 | 18.5 | ||

| CBA | 60 | 33 | 16.5 | 18.4 | ||

| CAA | 60 | 16.5 | 16.5 | 18.3 | ||

| BBB | 33 | 33 | 33 | 17.9 | ||

| BBA | 33 | 33 | 16.5 | 17.8 | ||

| BAA | 33 | 16.5 | 16.5 | 17.7 | ||

| AAA | 16.5 | 16.5 | 16.5 | 17.6 | ||

| MCU | DCU_1 | DCU_2 | DCU_3 | DCU_4 | |||

| EMC filter | EMC filter | EMC filter | EMC filter | ||||

| Basic unit | Nominal current | DCU Modules | Lenght | Weight | |||

| System configuration | IN / A (fs = 8 kHz) | qty | mm | kg | |||

CCCC | 60 | 60 | 60 | 60 | 4 | 796 | 25 |

| CCCB | 60 | 60 | 60 | 33 | 24.3 | ||

| CCCA | 60 | 60 | 60 | 16.5 | 24.2 | ||

| CCBB | 60 | 60 | 33 | 33 | 23.7 | ||

| CCBA | 60 | 60 | 33 | 16.5 | 23.6 | ||

| CCAA | 60 | 60 | 16.5 | 16.5 | 23.5 | ||

| CBBB | 60 | 33 | 33 | 33 | 23.1 | ||

| CBBA | 60 | 33 | 33 | 16.5 | 23 | ||

| CBAA | 60 | 33 | 16.5 | 16.5 | 22.9 | ||

| CAAA | 60 | 16.5 | 16.5 | 16.5 | 22.8 | ||

| BBBB | 33 | 33 | 33 | 33 | 22.4 | ||

| BBBA | 33 | 33 | 33 | 16.5 | 22.3 | ||

| BBAA | 33 | 33 | 16.5 | 16.5 | 22.2 | ||

| BAAA | 33 | 16.5 | 16.5 | 16.5 | 22.1 | ||

| AAAA | 16.5 | 16.5 | 16.5 | 16.5 | 22 | ||

| MCU | DCU_1 | DCU_2 | DCU_3 | DCU_4 | DCU_5 | |||

| EMC filter | EMC filter | EMC filter | EMC filter | EMC filter | ||||

| Basic unit | Nominal current | DCU Modules | Lenght | Weight | ||||

| System configuration | IN / A (fs = 8 kHz) | qty | mm | kg | ||||

| CCCCC | 60 | 60 | 60 | 60 | 60 | 5 | 946 | 30 |

| CCCCB | 60 | 60 | 60 | 60 | 33 | 29.5 | ||

| CCCCA | 60 | 60 | 60 | 60 | 16.5 | 29.4 | ||

| CCCBB | 60 | 60 | 60 | 33 | 33 | 28.8 | ||

| CCCBA | 60 | 60 | 60 | 33 | 16,5 | 28.7 | ||

| CCCAA | 60 | 60 | 60 | 16,5 | 16.5 | 28.6 | ||

| CCBBB | 60 | 60 | 33 | 33 | 33 | 28.2 | ||

| CCBBA | 60 | 60 | 33 | 33 | 16.5 | 28.1 | ||

| CCBAA | 60 | 60 | 33 | 16.5 | 16.5 | 28 | ||

| CCAAA | 60 | 60 | 16.5 | 16.5 | 16.5 | 27.9 | ||

| CBBBB | 60 | 33 | 33 | 33 | 33 | 27.6 | ||

| CBBBA | 60 | 33 | 33 | 33 | 16.5 | 27.5 | ||

| CBBAA | 60 | 33 | 33 | 16.5 | 16.5 | 27.4 | ||

| CBAAA | 60 | 33 | 16.5 | 16.5 | 16.5 | 27.3 | ||

| CAAAA | 60 | 16.5 | 16.5 | 16.5 | 16.5 | 27.2 | ||

| BBBBB | 33 | 33 | 33 | 33 | 33 | 27 | ||

| BBBBA | 33 | 33 | 33 | 33 | 16.5 | 26.9 | ||

| BBBAA | 33 | 33 | 33 | 16.5 | 16.5 | 26.8 | ||

| BBAAA | 33 | 33 | 16.5 | 16.5 | 16.5 | 26.7 | ||

| BAAAA | 33 | 16.5 | 16.5 | 16.5 | 16.5 | 26.6 | ||

| AAAAA | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 26.5 | ||

| MCU | DCU_1 | DCU_2 | DCU_3 | DCU_4 | DCU_5 | DCU_6 | |||

| EMC filter | EMC filter | EMC filter | EMC filter | EMC filter | EMC filter | ||||

| Basic unit | Nominal current | DCU Modules | Lenght | Weight | |||||

| System configuration | IN / A (fs = 8 kHz) | qty | mm | kg | |||||

| CCCCCC | 60 | 60 | 60 | 60 | 60 | 60 | 6 | 1096 | 35.2 |

| CCCCCB | 60 | 60 | 60 | 60 | 60 | 33 | 34.6 | ||

| CCCCCA | 60 | 60 | 60 | 60 | 60 | 16.5 | 34.5 | ||

| CCCCBB | 60 | 60 | 60 | 60 | 33 | 33 | 34 | ||

| CCCCBA | 60 | 60 | 60 | 60 | 33 | 16.5 | 33.9 | ||

| CCCCAA | 60 | 60 | 60 | 60 | 16.5 | 16.5 | 33.8 | ||

| CCCBBB | 60 | 60 | 60 | 33 | 33 | 33 | 33.3 | ||

| CCCBBA | 60 | 60 | 60 | 33 | 33 | 16.5 | 33.2 | ||

| CCCBAA | 60 | 60 | 60 | 33 | 16.5 | 16.5 | 33.1 | ||

| CCCAAA | 60 | 60 | 60 | 16.5 | 16.5 | 16.5 | 33 | ||

| CCBBBB | 60 | 60 | 33 | 33 | 33 | 33 | 32.7 | ||

| CCBBBA | 60 | 60 | 33 | 33 | 33 | 16.5 | 32.6 | ||

| CCBBAA | 60 | 60 | 33 | 33 | 16.5 | 16.5 | 32.5 | ||

| CCBAAA | 60 | 60 | 33 | 16.5 | 16.5 | 16.5 | 32.4 | ||

| CCAAAA | 60 | 60 | 16.5 | 16.5 | 16.5 | 16.5 | 32.3 | ||

| CBBBBB | 60 | 33 | 33 | 33 | 33 | 33 | 32.1 | ||

| CBBBBA | 60 | 33 | 33 | 33 | 33 | 16.5 | 32 | ||

| CBBBAA | 60 | 33 | 33 | 33 | 16.5 | 16.5 | 31.9 | ||

| CBBAAA | 60 | 33 | 33 | 16.5 | 16.5 | 16.5 | 31.8 | ||

| CBAAAA | 60 | 33 | 16.5 | 16.5 | 16.5 | 16.5 | 31.7 | ||

| CAAAAA | 60 | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 31.6 | ||

| BBBBBB | 33 | 33 | 33 | 33 | 33 | 33 | 31.5 | ||

| BBBBBA | 33 | 33 | 33 | 33 | 33 | 16.5 | 31.4 | ||

| BBBBAA | 33 | 33 | 33 | 33 | 16.5 | 16.5 | 31.3 | ||

| BBBAAA | 33 | 33 | 33 | 16.5 | 16.5 | 16.5 | 31.2 | ||

| BBAAAA | 33 | 33 | 16.5 | 16.5 | 16.5 | 16.5 | 31.1 | ||

| BAAAAA | 33 | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 31 | ||

| AAAAAA | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 30.9 | ||

Technology

SERVO PUMP (HYDRAULIC)

Whether servo steering pumps, servo pumps, hydraulic pumps or just steering, the servo steering pump supports the driver when turning the wheel in the stationary position, manoeuvring or driving at low speeds.

eSERVO APP software solutions:

- Sensorless control for PM motors – dynamic speed and torque control

- Needs-based flow control

- Adjustable AC motor speed

- Extended fault diagnostics – CAN error behaviour (warning, stop)

- High level of efficiency, low energy consumption – increases the range of the electric vehicle

- Low-noise

- Compact design, low weight

- Implementation of manufacturer-specific software solutions

- Plug & Play

AIR COMPRESSOR

Generates compressed air to supply all pneumatic systems (brakes, pneumatic doors, suspension systems, etc.) in mobile applications.

eAIR APP software solution:

- Sensorless control for PM motors – dynamic speed and torque control

- Adjustable AC inverter motor speed

- Extended fault diagnostics – CAN error behaviour (warning, stop)

- High level of efficiency, low energy consumption – increases the range of the electric vehicle

- Low noise and low-vibration

- Compact design, low weight

- Implementation of manufacturer-specific software solutions

- Plug & Play

HEAT MANAGEMENT

CO2 heat pumps are responsible for a holistic approach to thermal management in vehicles. They provide environmentally-friendly and energy-efficient heating and cooling energy and, for example, can heat up the passenger compartment or cool down the battery.

Heat pump – HEAT APP software solution:

- Sensorless control for PM motors – dynamic speed and torque control

- Adjustable AC motor speed

- Environmentally-friendly thermal management, e.g. for electric buses

- Efficient system solution – increases the range of the electric vehicle

- Implementation of manufacturer-specific software solutions

- Plug & Play

T6 MCU Mobile Control System

MCU software ensures complete operation of the entire system. Download files can also be saved on the MCU’s file system.

- MCU (Main Control Unit) – as an embedded control system (PLC)

- IEC 61131-3 programming environment, CODESYS-based, freely programmable

- Variable communication link to the vehicle’s control system (ECU) and diagnostics

- J1939 or CANopen gateway

- Platform for application-specific software solutions

- T6 wizard provides support during commissioning

J1939 CAN APP

The J1939 CAN APP provides a communication gateway in the T6 APD system for exchanging process data, settings and diagnostics messages (DM1 ... DM4) via SAE J1939.

UDS APP

Unified Diagnostic Services (UDS) is a communication protocol used in diagnostics. The ISO 14229-1 standard describes various services. The T6 APD supports a specific number of services.

TSC APP

TSC – Torque Speed Control: generic application for easy control of an auxiliary system’s speed and torque via J1939.

PDG APP

PDG – Process Data Gateway: generic application enabling access to all of the auxiliary system’s settings via J1939.

Enables all conceivable axis functions to be controlled via CAN.

DRIVE APP

Application for operating an additional device without CAN controls. Speed setting using APP parameters.

HEAT APP

- Sensorless control for PM motors – dynamic speed and torque control

- Adjustable AC motor speed

- Environmentally-friendly thermal management, e.g. for electric buses

- Efficient system solution – increases the range of the electric vehicle

- Implementation of manufacturer-specific software solutions

- Plug & Play

eAIR APP

- Sensorlose Steuerung für PM-Motor – Dynamische Drehzahl- und Drehmomentsteuerung

- AC-Wechselrichter-Motordrehzahl einstellbar

- Erweiterte Fehlerdiagnose – CAN-Fehlerverhalten (Warnung, Stopp)

- Hoher Wirkungsgrad, niedriger Energieverbrauch – erhöht die Reichweite des E-Fahrzeugs

- Geräusch- und vibrationsarm

- Kompakte Bauweise, geringes Gewicht

- Implementierung von herstellerspezifischen Softwarelösungen

- Plug & Play

eSERVO APP

- Sensorless control for PM motors – dynamic speed and torque control

- Needs-based flow control

- Adjustable AC motor speed

- Extended fault diagnostics – CAN error behaviour (warning, stop)

- High level of efficiency, low energy consumption – increases the range of the electric vehicle

- Low-noise

- Compact design, low weight

- Implementation of manufacturer-specific software solutions

- Plug & Play

SAFETY AND SECURITY

Our development phases depend on ASIL and SIL. Operational safety and cyber security use similar development processes. Here, the focus is on identifying and assessing the hazards and risks that can arise from the intended functions. Cyber security is a multi-dimensional concept that covers the entire technical life cycle and the whole organisation of a company. As regulation UN R155 is relevant to the type approval (homologation) of electric vehicles, it primarily concerns vehicle manufacturers. However, suppliers must also be able to demonstrate the cyber security of their products, internal processes and services.

In use in these areas of application

E-MOBILITY

With innovative solutions, KEB enables the electronic operation of auxiliary systems in commercial vehicles and mobile machinery, thereby reducing emissions.