- Display size 4,3“ – 15,6“

- Resistive touch

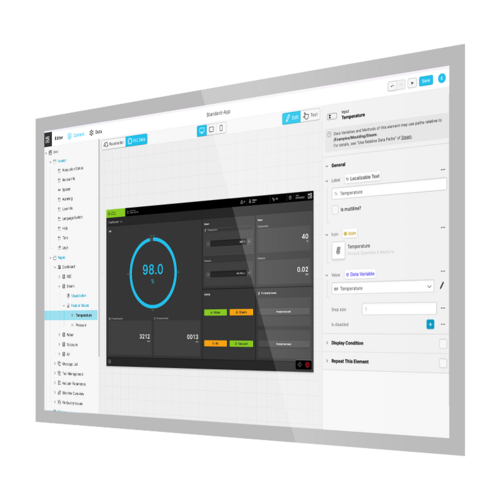

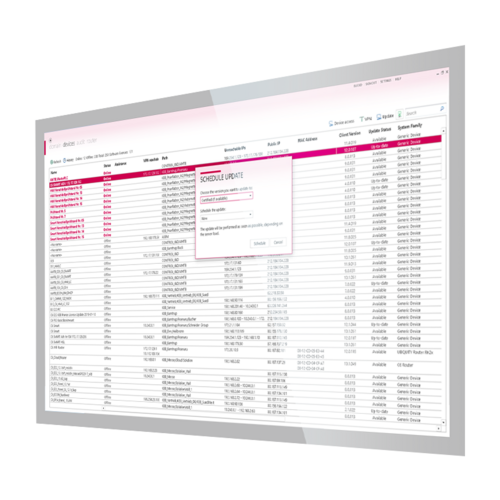

- HMI, remote maintenance

Innovative Hard- and Software for your Application

The KEB range offers extensive hardware solutions combined with excellent software functionalities, from the HMI through to the motion profile.

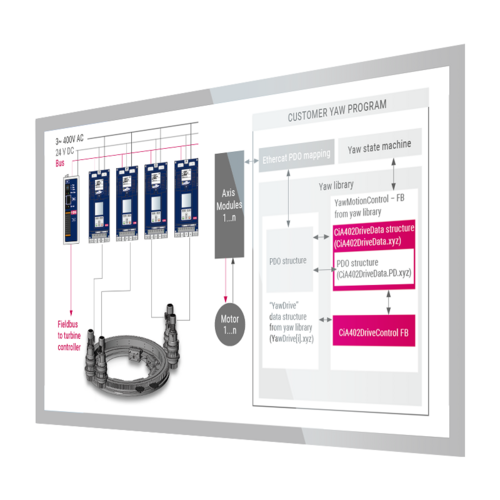

The wide-ranging product portfolio starts with the compact C6 COMPACT II and extends to the powerful C6 P34 which is available in the form of a Box, Panel or Book Mount IPC. With the C6 Safety PLC and the Safety I/O, KEB also offers a certified safety controller with safe inputs and outputs that comply with safety standards IEC 61508 SIL 3 and DIN EN ISO 13849-1 PLe. Communication takes place via the existing EtherCAT bus with the certified Safety over EtherCAT (FSoE) safety protocol.

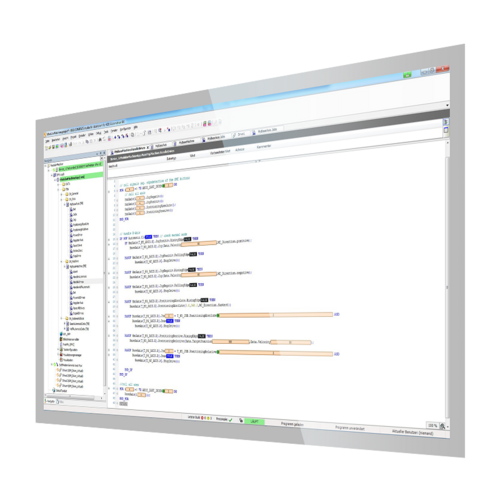

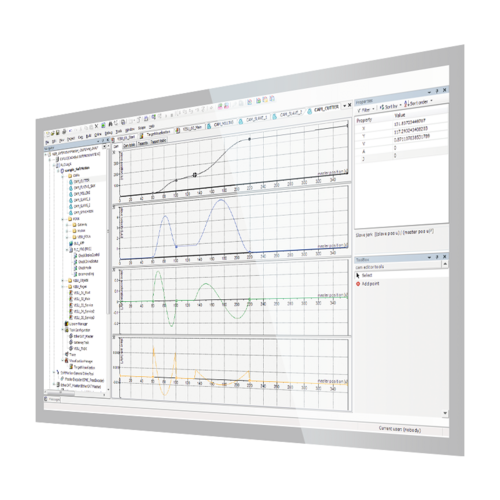

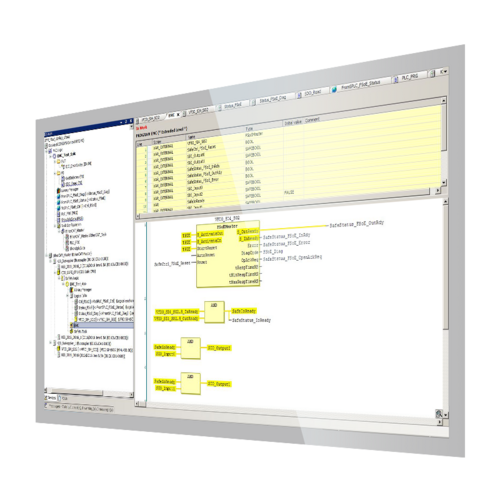

In addition to hardware, KEB also offers the COMBIVIS studio 6 and COMBIVIS studio HMI development environment, combining assistant-guided component selection, fieldbus configuration, drive parametrisation as well as IEC 61131-3 project generation and motion control.

- Customer focus as a priority

- Years of experience in development

- Reliable solutions

The intelligent automation suite from KEB combines assistant-guided component selection, fieldbus configuration, drive parametrisation as well as IEC 61131-3 project generation and motion control. From the planning and layout phase to the implementation of control sequences and multi-axis movement profiles right through to the start-up and fine tuning phases, the user is supported by a tool developed by experienced application engineers. Based on the extensive device, library and template database, solutions for the widest range of applications can be generated quickly and easily.